Motors

The motors that power our lives are energy-intensive. Improving efficiency will reduce grid strain and greenhouse gases.

Everything you need to know about motors

Where are motors used?

Motors are essential to most automated processes, including those that drive home appliances. From refrigerators and air conditioners to water pumps and factory machines, any product with a pump, fan, or compressor needs a motor. They’re key to the world’s manufacturing, mining, agriculture, transportation, and residential sectors.

While they are common around the world, motors are most heavily used in places with advanced industrial sectors like China, the European Union, and the United States. Emerging economies like Brazil and India are increasingly using more of them as industrialization and urbanization increase.

How do motors work?

Motors work by using magnets or electromagnets (that is, coils of wire carrying electricity) to create a magnetic field. This magnetic field then interacts with electrical current to create mechanical energy that causes a rotor to spin, which drives machinery ranging from small appliances to large industrial equipment.

Motors function as part of a larger entity called an electric motor system. These systems bring together all the components needed to convert electrical energy into mechanical energy: the motor plus the equipment it drives, such as a compressor, pump, or fan.

How do energy-efficient motors benefit people and planet?

Today, electric motor systems account for 53%1 of global electricity demand. Much of this demand can be attributed to the fact that low-efficiency, outdated motors represent two-thirds of the global motor stock. This high energy consumption leads to unnecessary greenhouse gas emissions and strains power grids.

Fortunately, there’s a solution: efficiency. Energy-efficient motors are designed to consume less electricity when performing a task, whether it’s spinning a fan, driving a pump, or turning a conveyor belt. Shifting the global motor stock to modern, efficient models would have major environmental and social benefits.

There are many ways to improve the efficiency of motors and motor systems. Using better materials, such as higher-quality steel, can reduce energy loss from heat, friction, and magnetic inefficiency. Fitting motor components together more precisely minimizes mechanical losses and vibrations. Pairing motors with variable-speed drives (VSDs), which adjust motor speed to match actual demand, lowers energy consumption. Digitalization of motor systems also improves efficiency, as it facilitates better monitoring, control, and maintenance.

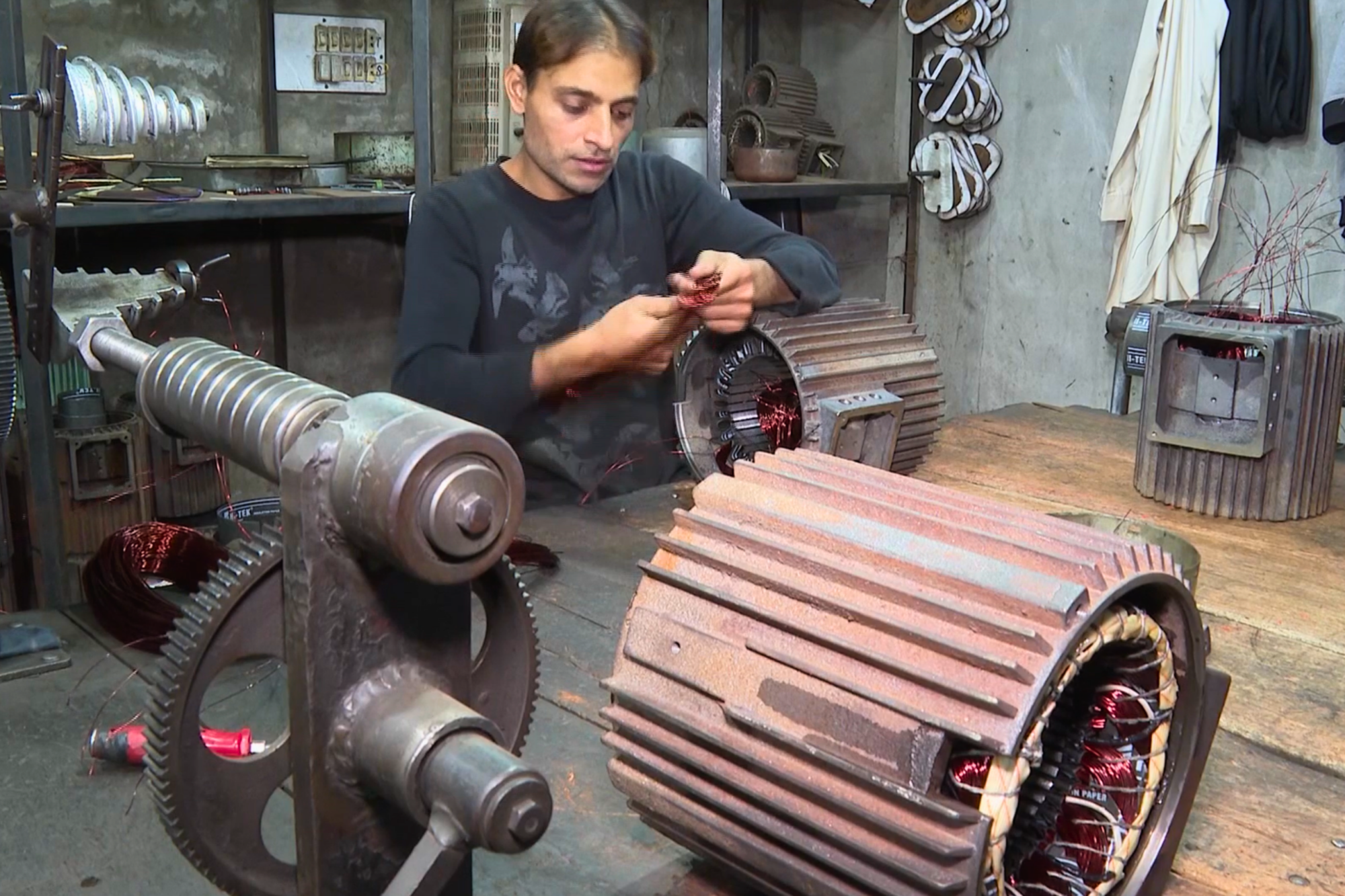

One barrier standing in the way of getting these improvements into the world at the scale required is cost. Because industrial motors and motor-driven systems are expensive to install, they have a surprisingly long shelf life. In fact, one study found that they typically remain in operation twice as long as their expected lifetime.2 Motors also tend to be repaired instead of replaced, and sometimes become less efficient with each repair.

CLASP has identified 10 appliances critical to fighting climate change and improving people's lives. Motors are one.

[Photo: CLASP]

[Photo: Shutterstock]

[Photo: CLASP]

What is the solution?

Improving the energy efficiency of electric motors and electric motor-driven systems can significantly reduce electricity demand and curb climate emissions.

How can we achieve this solution?

Governments

- Incentivize motor replacement to ensure widespread adoption of efficient motors.

- Regulate and protect national markets to prevent inefficient and outdated motors from being imported.

- Develop and implement national standards and labelling policies as well as testing facilities to encourage maximum efficiency and increase energy and cost savings for motors and motor systems.

Motor manufacturers

- Ensure that the motors and motor systems produced adhere to high global standards of efficiency.

- Use variable speed drives (VSDs) on motors to adjust the speed and replace the need for a mechanical brake.

- Design and operate motor systems to minimize energy loss and maximize efficiency.

- Increase the digitalization of motor systems to enable monitoring, control, and maintenance.

Businesses that use motors

- Train teams and ensure procurement of motors with higher efficiency ratings to reduce power demand, lower running costs, and increase competitiveness.

- Inspect and assess motors and motor systems regularly to maintain efficiency.

- Switch off motors and motor systems when not in use to reduce energy waste.

- Install monitoring systems to measure efficiency and flag any energy waste.

Recent News

Are you a policymaker working on motors? Explore CLASP's free tools:

Net Zero Appliances NDC Toolkit

- Learn how (and why) to maximize the potential of appliance efficiency in NDCs.

World's Best MEPS: Tracking Leaders in Appliance Energy Efficiency Standards

- Find the world’s most ambitious energy performance standards for six key appliances and equipment.

Mepsy: The Appliance & Equipment Climate Impact Calculator

- Analyze efficiency policy options for key appliances across 162 countries.

CLASP's work on motors impacts:

0. ”The Motor Driven Unit Policy Guidelines”, IEA, 2017. https://www.iea-4e.org/projects/the-motor-driven-unit-policy-guidelines/.

1. Tieban, Rolf et al. ”EASY – Lessons learned from four years of the Swiss EASY audit and incentive program”, Impact Energy Inc., September 2015. https://www.topmotors.ch/sites/default/files/2018-06/E_PB_2015_09_EEMODS15_Paper_Tieben_Werle_Brunner_EASY.pdf.