Economies Can Boom When Powered by Efficient Motor Systems

Efficient motors systems offer a turn-key opportunity for both established and emerging manufacturing countries.

Motors are the invisible heartbeat to economic progress. They are found across industrial facilities, powering production lines for goods like metals, paper, cement, textiles, and packaged food and beverages. Energy efficient motors and their associated components are key tools to enable economic growth, but inefficient ones can hinder progress via high energy demand and associated costs.

A golden opportunity

Efficient motors systems offer a golden opportunity for all countries –from existing economic powerhouses to newly industrializing nations– to expand and thrive in global markets while simultaneously slashing energy costs and emissions.

Motor systems 101

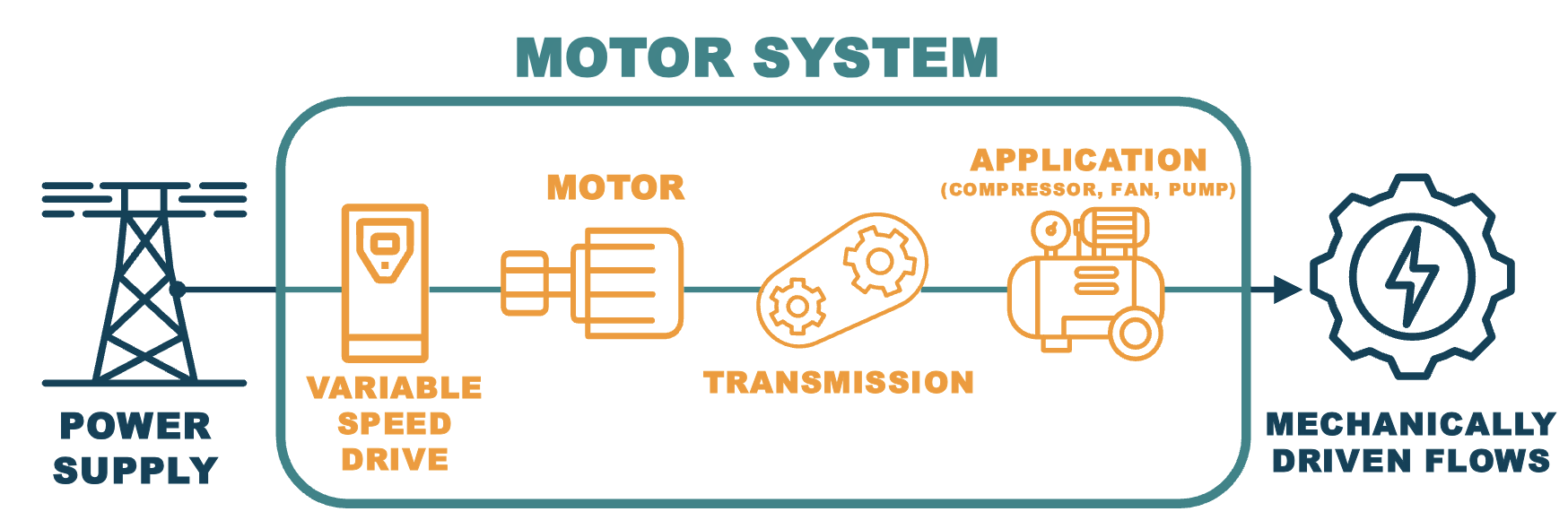

Industrial motors, like those found in factories, are part of a system of several components. When evaluating efficiency, governments and the private sector must look at and address the whole system, from power source to mechanical output. These systems are responsible for powering many recognizable factory features like conveyer belts and air compressors.

Inefficient motor systems lock in years of downsides

Without intervention to ramp up efficiency, motor systems will account for 25% of global energy demand and 33% of global energy related emissions by 2050.

And these inefficiencies are expensive: continued use of outdated motor systems will be responsible for $9 trillion of lost GDP in 2050.

Outdated and inefficient motors represent two-thirds of today’s global stock. These motors can last upwards of 15 years, locking countries into a future of high energy consumption, unnecessary emissions, and strained power grids.

More efficient industry is the key to economic progress

Increasing the market share of efficient motor systems for all economies offers significant and sustained benefits. A timely transition will require leaders to push the boundaries on policymaking and financing.

Heavily industrialized countries, like China and the European Union, need to replace existing inefficient motor stock with the most efficient IE5 compliant technologies and pair them with variable speed drives to achieve the biggest cost and climate benefits. This move can be catalyzed by ambitious efficiency policy and will require significant financing support from sources like industrial banks.

In countries where manufacturing is expected to grow significantly, with commensurate increase in motor stock, like Nigeria and Indonesia, quick government action to incentivize or require efficient motor systems in new factories will prevent runaway emissions and costs from the start. External financial support and mechanisms, like subsidies and bulk procurement, will be critical for supporting emerging industry.

CLASP supports leaders in getting the most out of motors

Efficient motors systems have been available for decades, but barriers to entry, like cost and expertise, have slowed adoption. CLASP is supporting government and industry leaders in seizing the opportunity for big economic and climate wins through innovative policy and industrial initiatives.

- In China, where world-leading motor system efficiency policies are in place, CLASP funded a pilot project at six sites to measure the performance of motor systems in air compressors – a key piece of factory equipment. The data from these informed new voluntary national standards.

- In India, CLASP’s market research and analyses are helping policymakers build the case for ambitious efficiency policy improvement and revised motor labeling classes that will empower industry to choose more efficient equipment.

- In Nigeria and Indonesia, our experts are working with policymakers to gather market data to inform new motor efficiency requirements.

- In Pakistan, CLASP and partner, SAMA^verte, created an Industry Accelerator program, aimed at building the expertise of local manufacturers and helping improve their ability to produce more efficient motors.

To explore more of CLASP’s motor work, check out our motors page and news section.