Improving Appliances, Changing Lives: Pakistan’s Industry Accelerator

CLASP's Industry Accelerator program in Pakistan aims to transform the motor and water heater manufacturing sectors, to produce more efficient and quality products.

CLASP's Industry Accelerator in Pakistan

This Industry Accelerator has two main components: strengthen capacity for testing labs and provide technical support for manufacturers to improve their products to prepare for the upcoming regulations.

The Need for Reliable Testing Laboratories

In Pakistan’s appliance and equipment manufacturing sector, reliable, independent appliance test laboratories are starting to emerge. Test labs support manufacturers in assessing efficiency levels of their appliances, and their presence is crucial to accelerating efficiency, innovation and quality. They will also be essential in measuring the performance of regulated products for compliance once Minimum Energy Performance Standards (MEPS) and labeling regulations are rolled out.

Strengthening Lab Capacity Through Partnerships with Private Sector

Recognizing the need for both industry-based and independent test laboratories that are able to provide reliable and accurate test results, CLASP facilitated public-private partnerships with major air conditioner and motor manufacturers in Pakistan. CLASP also collaborated major manufacturers to support the capacity building of existing labs such as Centre for Energy Research & Development, Pakistan (CERAD). The training included upskilling the lab technicians’ proficiency in protocols, test methodologies, and enhancing verification process to prove that testing is reliable.

Learning from International Best Practice

CLASP partnered with motor testing expert from Turkish National Standards Institute (TSE) who are working in Pakistan and remotely to help strengthen the capacity of three motors labs at the Information Technology University (ITU), the Gujranwala Institute of Future Technology (GIFT) and CERAD. TSE have provided advice not only on lab equipment set up, but have undertaken extensive testing alongside the Pakistani technical staff to ensure their ability to test products and analyze results according to the IEC testing standards.

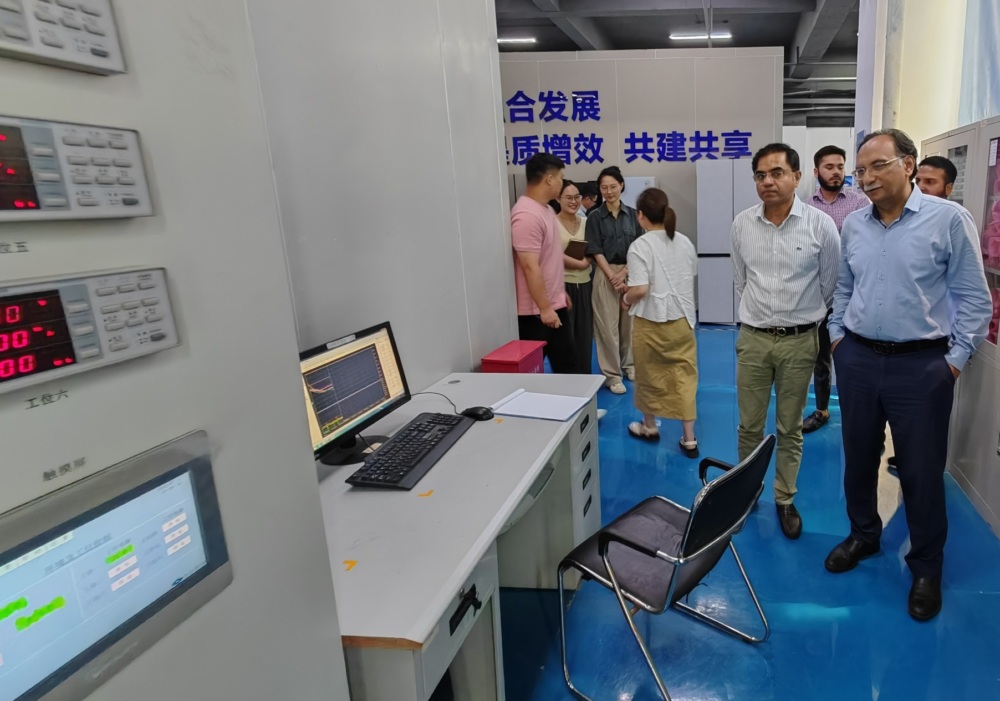

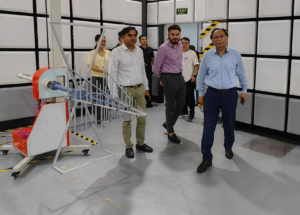

To gain insights on producing more efficient water heaters, a delegation of Pakistani manufacturers visited China’s renowned testing lab, the China Household Electric Appliance Research Institute (CHEARI) in Beijing. The manufacturers had an opportunity to enhance their knowledge of test lab equipment, methodologies and processes and learn insights in designing more efficient water heaters. When efficient water heaters are produced in Pakistan they will reduce the fossil fuel demand, strain on national grid, lower emissions and lessen monthly power bills for consumers.

Strengthening the Motor Industry

CLASP also invited motor experts from EMOSAD in Türkiye to visit local counterparts in Pakistan to share insights on how the country transformed from producing low-efficiency motors to building globally competitive, energy-efficient models. Following initial assessment of manufacturer production facilities, the experts have been preparing tailored design and production improvement recommendations for each participant considering their existing capabilities and objectives. The overall goal is to enable all participating manufacturers to have the capacity to produce motors of at least IE1 efficiency levels.

Industry Support Yield Benefits for Manufacturers, Consumers and the Climate

Around the world, manufacturers are recognizing the benefits of producing appliances and equipment that adhere to global standards in energy-efficiency that are also crucial to climate action and sustainable development. The presence of reliable, independent appliance test laboratories and technical assistance to participating manufacturers are the first steps towards building thriving motor and water heater industries in Pakistan. This will benefit the climate, the economy and consumers.

CLASP would like to thank the following companies who are a key part of the Pakistan Industry Accelerator program: AC and Motor Test Laboratories at CERAD, ITU and GIFT; the Punjab Energy Department (PEECA); Haier, ABB, Dawlence; the Pakistan Council of Scientific and Industrial Research (PCSIR); the Turkish National Standards Institute (TSE); the Turkish Motor Manufacturer’s Association (EMOSAD); the Pakistan Pumps and Motor Manufacturers Association (PPEMMA); the China Household Electric Appliance Research Institute (CHEARI); and the participating manufacturers Canon, Super Asia, Waves, Golden Fuji, Fisher, Golden Dynamics, El-Khas, Sunrise and Shahzad Pump.